These load cells are well suited to materials testing machines and other applications requiring a rugged load sensor.

Pancake load cell installation.

The selection is mainly based on the site installation environment and installation dimensions.

The standard electrical output for our pancake load cells is mv v.

Avoid getting moisture in the connector on the pancake cell or the end of the cable while installing the load cells.

Remove the plated connector cover on the side of the pancake assembly and screw in the interface cable tightly.

High accuracy paired with high overload capacity makes it a popular choice for materials testing overhead and low profile weighing.

Column type load cell.

Nearly all of these pancake load cells can be specified with high level analog voltage analog current or digital outputs.

Often ideal for high.

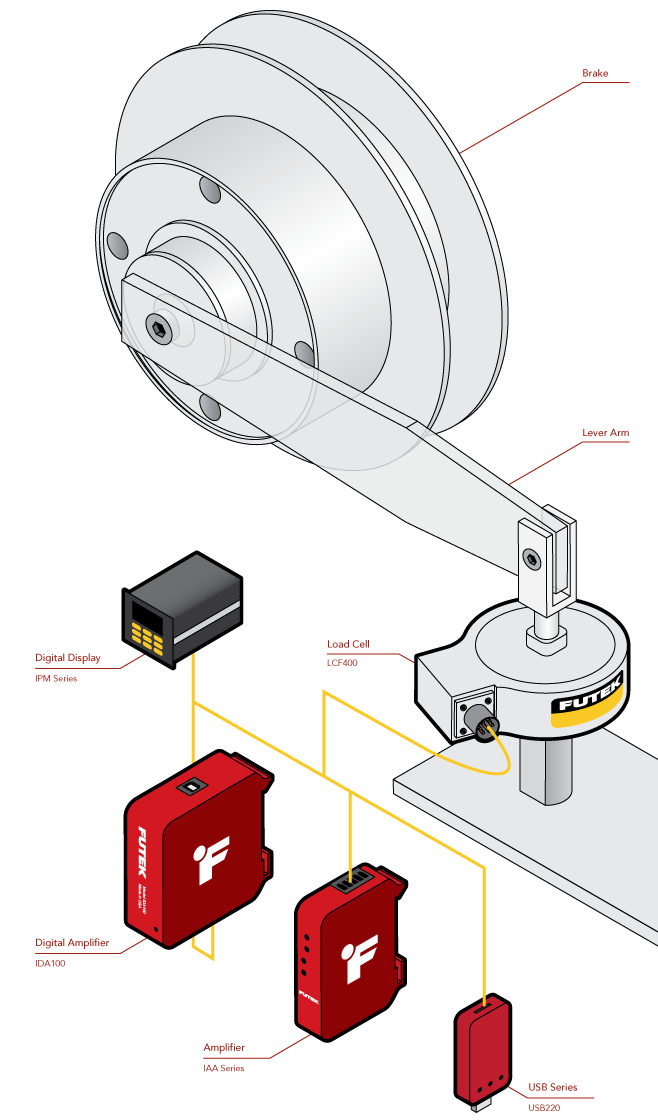

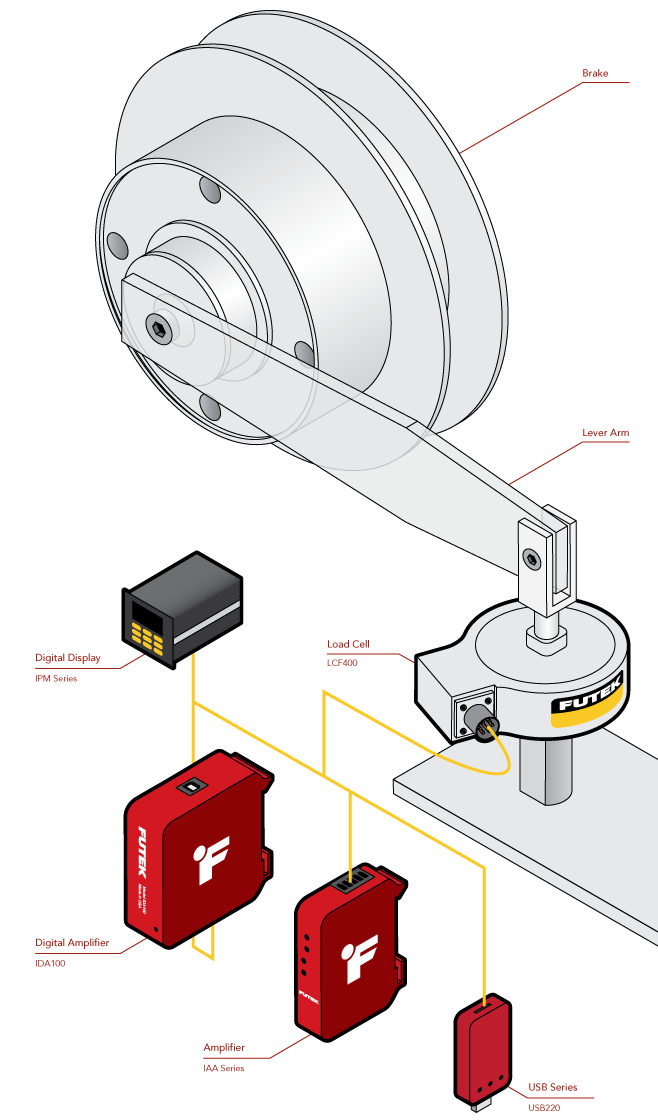

Types of load cell mountings.

Load cell static accuracies range from 0 03 of full scale output to 0 10 of full scale output.

Lchd 25 all models shown proportionally smaller than actual size.

With the largest selection of quality load cells available in stock nobody offers faster more reliable service.

Some other more advanced types of load cell installations.

The pancake load cell has a shorter height and a larger diameter and the column type load cell height is higher and the diameter is smaller.

Our experienced engineering and design staff create the most comprehensive line of load cells and weigh modules available.

Constructed of alloy steel and sealed to ip67 it also has recessed holes for flush mounting.

Lchd 100 lchd 2k lchd 7 5k lchd 30k lchd 75k lchd 150k m odels with built a vailable i n a.

See next page for dimensions.

Some other more advanced types of load cell installations for specific uses include helical fiber optic.

Offered with industry standard bolt patterns and a threaded through hole design these load cells come in a variety of sizes ranges and outputs.

The difference is in installation.

In addition to typical installations of hydraulic pneumatic and strain gage types of load cells omega customers often ask about bending beam load cells shear beams canister type ring and pancake load cells and button and washer type load cell mounting.

The difference in.

Pancake load cell model 3173 description the model 3173 covers the lower capacity ranges of 200 pounds force to 3000 pounds force while exhibiting the high performance characteristics of stiffness and accuracy.

Once connected to the pancake load cell run the cable from each load cell over to the summing box.

Installation u 5 point calibration u mating connector included low profile pancake style load cells standard and metric models lchd 5k shown actual size.

Pancake load cells capable of measurement in both tension and compression often called universal load cells provide reliable feedback of both parameters in a single installation.